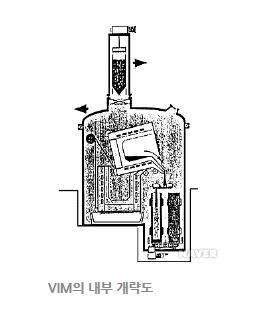

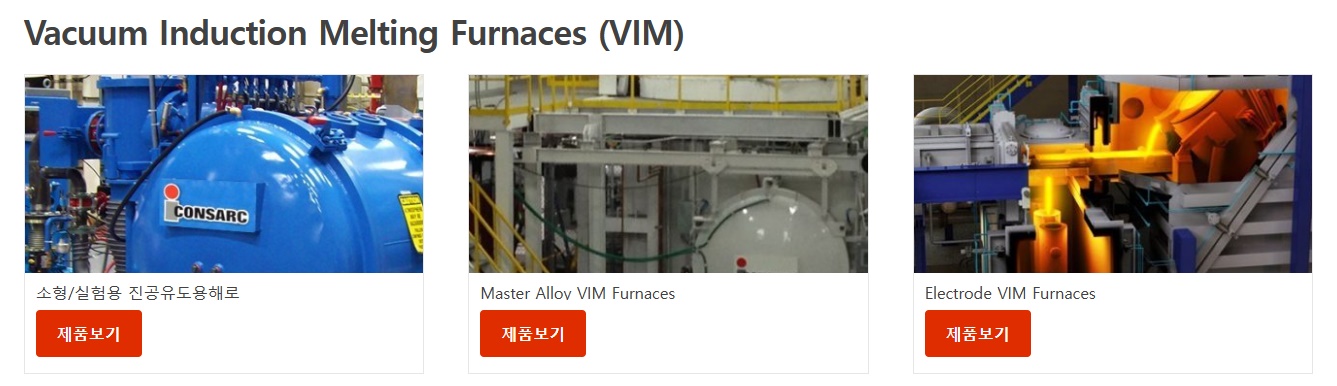

VIM (Vaccum Induction Melting) 진공 유도 용해로

진공 tank 내에 유도로를 설치하여 진공중에서 장입, 용해, 주조하는 용해로를 말하며 활성Ti, Al원소의 산화방지, 회수율 증대 및 강중수소, 질소 등의 가스를 제거한다. 전기로 및 대기유도로와 동일한 1차용해로로서 항공기부품 주조재, 자동차 내열주조재등 특수강 잉곳(Ingot)을 제조할 수 있다. 진공 아크 재용해로(VAR) 및 일랙트로 슬래그 재용해로(ESR) 등 2차 재용해로와 결합하여 고급강 등을 생산할 수 있다.

[네이버 지식백과] VIM [vaccum induction melting] (철강용어사전)

Vacuum induction melting (VIM) utilizes electric currents to melt metal within a vacuum. The first prototype was developed in 1920.

Induction heating induces eddy currents within conductors. Eddy currents create heating effects to melt the metal.

Vacuum induction melting has been used in both the aerospace and nuclear industries.

VIM involves placing a core-less induction furnace into a vacuum chamber.

The melting and casting operations are carried out at low pressures to control the entire alloy chemistry process.

VIM is used in particular for producing alloys with melting points beyond those practical for other kinds of melting. Nickel, nickel-iron, and superalloys are frequently produced using this process. The VIM process is often used for small batch sizes and allows for a high level of control over the composition of the alloy. There is low environmental contamination (dust etc) and oxidation, while elements that are often undesired such as hydrogen or nitrogen can be removed from the process.

'잡학피디아' 카테고리의 다른 글

| 토스뱅크 atm 출금 수수료 무료 맞나? (1) | 2023.02.07 |

|---|---|

| ESR 뜻 (Electro Slag Remelting) (0) | 2023.02.03 |

| 종합소득세 직장인도 내야할까? 확인해보자 (0) | 2023.01.30 |

| 가짜식욕 생길때 써볼 억제 방법 5가지 정리해봄 (0) | 2023.01.19 |

| 닥터 코퍼(Dr. copper)란? 구리 관련주, 구리 가격 정리 (0) | 2023.01.18 |